System for flammeskjæringPFEIFER technology & innovation Plauen D

skyTUBE Pro 6500 3D RohrLaseranlage 6kW

System for flammeskjæring

PFEIFER technology & innovation Plauen D

skyTUBE Pro 6500 3D RohrLaseranlage 6kW

Produksjonsår

2026

Tilstand

Ny

Plassering

Plauen

Bilder viser

Vis kart

Data om maskinen

- Maskinbetegnelse:

- System for flammeskjæring

- Produsent:

- PFEIFER technology & innovation Plauen D

- Produksjonsår:

- 2026

- Tilstand:

- ny

- Funksjonalitet:

- fullt funksjonell

Pris og beliggenhet

- Plassering:

- Rathenaupl. 8, 08525 Plauen, Deutschland

Ring

Tekniske detaljer

- Arbeidsområde:

- 6 500 mm

- Type innstrømsstrøm:

- trefaset

- Total bredde:

- 1 629 mm

- Total høyde:

- 2 525 mm

- Total lengde:

- 10 500 mm

- Bordlengde:

- 6 500 mm

- Totalvekt:

- 5 500 kg

- Effekt:

- 15 kW (20,39 hk)

- Laser effekt:

- 6 000 W

- Garantiperioden:

- 24 måneder

- Utstyr:

- kjøleenhet, sikkerhetslysbarriere

Detaljer om tilbudet

- Annonse-ID:

- A14903902

- Referansenummer:

- skyTUBE6500 FIBER

- Oppdatering:

- sist oppdatert 09.02.2026

Beskrivelse

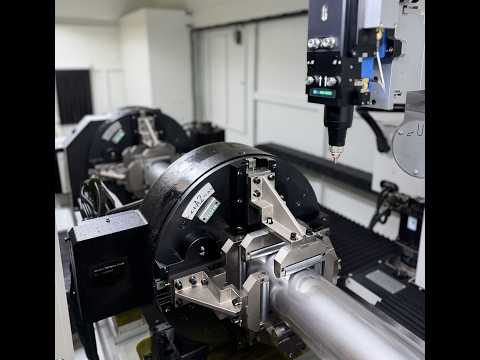

PFEIFER technology skyTUBE Pro 6500 X3 – Profile and Tube Laser Centre 6500 x 15–160 mm Format

The skytube-pro-6500×3 profile and tube laser fiber laser metal cutter offers fast material changeover with up to 6kW, making it an efficient solution for your production needs. It is the clever and highly effective tube laser processing solution for round tubes, square tubes, rectangular tubes, open profiles, and special profiles cutting. This laser machine ensures maximum productivity during production changes. The challenge: fiber laser up to 6kW for numerous metal processing applications!

Njdsrh Iw Tspfx Ad Asku

Unmatched Laser Cutting Performance

High axis speeds and accelerations combined with a stable mechanical structure deliver excellent cutting performance and precision. The tube and profile laser processing machine for production is compact and intelligently designed—smart solutions 100% made in Saxony!

Tubes and profiles from 15x15 to 160x160 mm 3D cutting using efficient fiber laser technology

The semi-automatic 6-position profile-tube loading chain system allows for rapid job changes. With the optional bundle loader, you can work independently.

Bevel Cutting

A feature that changes everything. Thanks to our machine’s ability to tilt the cutting head up to 50° on an additional fifth axis, we offer a solution to one of the major challenges in contemporary profile processing. When the laser beam always hits the workpiece at a right angle, it produces an elliptical cutting edge. By enabling the tube laser cutting head to tilt in conjunction with the feed axis, a precisely angled cut can now be achieved.

The skyTUBE Laser ensures maximum safety in operation!

The skyTUBE Pro is a Class 1 laser system. There is no risk of contact with laser emissions or reflections during operation. For all our laser systems, nothing is more important than absolute safety as well as full compliance with the highest standards and regulations.

Technical specifications:

- Enclosed industrial housing, Class 1 laser system, optionally Class 4

- Working area – tube cutting system/clamping system: Standard tubes from 15 to 160 mm, rectangular tubes 15 x 15 – 110 mm

- Working area on tube X 6500 Y±100 Z 150 A ±360° U ±50°

- Automatic material feed for up to 6 x 160 mm profiles, 3500 – 7000 mm

- Automatic material unloading system for profile sections, structure adjusted to profile length

- Z-drive system: Ball screw axis system with PTI SVZ System

- X/Y drive system: Linear axis system with PTI AC-SERVO System

- Productive cutting speed: depending on material and laser configuration, up to 50 m/min / 1.4G

- Software resolution: up to 2500 DPI

- Repeat accuracy: ±0.03 mm

- Max. footprint dimensions (W x D x H): 11600 mm x 2830 mm x 2100 mm + unloading system according to profile cut length

Annonsen ble oversatt automatisk. Oversettelsesfeil kan forekomme.

The skytube-pro-6500×3 profile and tube laser fiber laser metal cutter offers fast material changeover with up to 6kW, making it an efficient solution for your production needs. It is the clever and highly effective tube laser processing solution for round tubes, square tubes, rectangular tubes, open profiles, and special profiles cutting. This laser machine ensures maximum productivity during production changes. The challenge: fiber laser up to 6kW for numerous metal processing applications!

Njdsrh Iw Tspfx Ad Asku

Unmatched Laser Cutting Performance

High axis speeds and accelerations combined with a stable mechanical structure deliver excellent cutting performance and precision. The tube and profile laser processing machine for production is compact and intelligently designed—smart solutions 100% made in Saxony!

Tubes and profiles from 15x15 to 160x160 mm 3D cutting using efficient fiber laser technology

The semi-automatic 6-position profile-tube loading chain system allows for rapid job changes. With the optional bundle loader, you can work independently.

Bevel Cutting

A feature that changes everything. Thanks to our machine’s ability to tilt the cutting head up to 50° on an additional fifth axis, we offer a solution to one of the major challenges in contemporary profile processing. When the laser beam always hits the workpiece at a right angle, it produces an elliptical cutting edge. By enabling the tube laser cutting head to tilt in conjunction with the feed axis, a precisely angled cut can now be achieved.

The skyTUBE Laser ensures maximum safety in operation!

The skyTUBE Pro is a Class 1 laser system. There is no risk of contact with laser emissions or reflections during operation. For all our laser systems, nothing is more important than absolute safety as well as full compliance with the highest standards and regulations.

Technical specifications:

- Enclosed industrial housing, Class 1 laser system, optionally Class 4

- Working area – tube cutting system/clamping system: Standard tubes from 15 to 160 mm, rectangular tubes 15 x 15 – 110 mm

- Working area on tube X 6500 Y±100 Z 150 A ±360° U ±50°

- Automatic material feed for up to 6 x 160 mm profiles, 3500 – 7000 mm

- Automatic material unloading system for profile sections, structure adjusted to profile length

- Z-drive system: Ball screw axis system with PTI SVZ System

- X/Y drive system: Linear axis system with PTI AC-SERVO System

- Productive cutting speed: depending on material and laser configuration, up to 50 m/min / 1.4G

- Software resolution: up to 2500 DPI

- Repeat accuracy: ±0.03 mm

- Max. footprint dimensions (W x D x H): 11600 mm x 2830 mm x 2100 mm + unloading system according to profile cut length

Annonsen ble oversatt automatisk. Oversettelsesfeil kan forekomme.

Dokumenter

Tilbyder

Merk: Registrer deg gratis eller logg inn, for å få tilgang til all informasjon.

Registrert siden: 2011

Send forespørsel

Telefon & Faks

+49 3741 ... annonser

Disse annonsene kan også være av interesse for deg.

Annonse

Plauen

Plauen

1 133 km

Rør- og profil-laserkuttemaskin

PFEIFER technology & innovation Plauen DskyTUBE Pro 6500 3D RohrLaseranlage 6kW

PFEIFER technology & innovation Plauen DskyTUBE Pro 6500 3D RohrLaseranlage 6kW

Annonse

Leipzig

Leipzig

1 046 km

Laserskjæremaskin

12 m Rohrlaserschneidmaschine 12 kW12045ETP / 450 mm Option bis 510 mm

12 m Rohrlaserschneidmaschine 12 kW12045ETP / 450 mm Option bis 510 mm

Annonse

Grebenau

Grebenau

1 085 km

Automatisk stanse- og bøyemaskin

BIHLERRM 35

BIHLERRM 35

Annonse

Deinze

Deinze

1 102 km

Rørbøyemaskiner

ArloSPB60 CNC

ArloSPB60 CNC

Annonse

Loire

Loire

1 647 km

Fiber Laser Tube skjæremaskin

Bodor T2

Bodor T2

Annonse

Saerbeck

Saerbeck

924 km

Laserskjæremaskin

DURMAVorführ Rohrlaser HD-TC 60250 COMPACT

DURMAVorführ Rohrlaser HD-TC 60250 COMPACT

Annonse

Gondelsheim

Gondelsheim

1 269 km

Kranbaldakin Kranportalkran

Demag Hallenkran Brückenkran KranDKUN 10 ELKE 1600Kg 1,6t - Spur 11785mm

Demag Hallenkran Brückenkran KranDKUN 10 ELKE 1600Kg 1,6t - Spur 11785mm

Annonse

Enschede

Enschede

923 km

Rørlaserskjæringsmaskiner

Bodor K2

Bodor K2

Annonse

Debrecen

Debrecen

1 663 km

Laserskjæremaskin

TRUMPFTruLaser Tube 7000 fiber

TRUMPFTruLaser Tube 7000 fiber

Annonse

Ludwigsstadt

Ludwigsstadt

1 125 km

Børste avgradingsmaskin

WeberTTS-1100

WeberTTS-1100

Annonsen din har blitt slettet

Det har oppstått en feil