BåndkutterCORMAK

HBS320

Båndkutter

CORMAK

HBS320

fast pris pluss MVA

€ 1 670

Produksjonsår

2025

Tilstand

Ny

Plassering

Siedlce

Bilder viser

Vis kart

Data om maskinen

Pris og beliggenhet

fast pris pluss MVA

€ 1 670

- Plassering:

- Brzeska 120, 08-110 Siedlce, Polska

Ring

Detaljer om tilbudet

- Annonse-ID:

- A8117426

- Oppdatering:

- sist oppdatert 16.12.2025

Beskrivelse

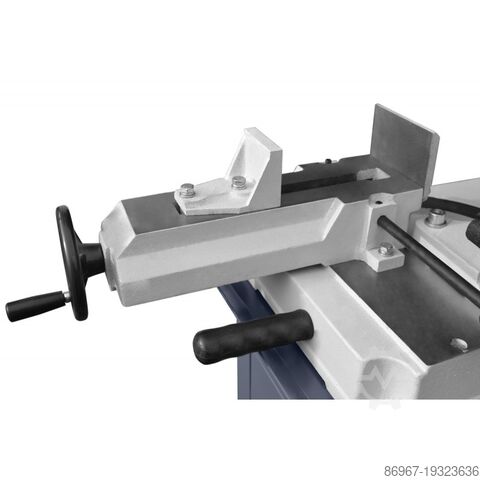

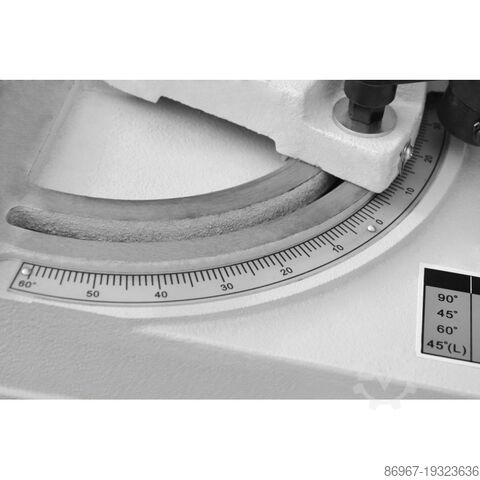

CORMAK HBS320 for double-sided miter cutting within a range from -45 to +60 degrees. The machine’s design is based on solutions and projects by Polish engineers. Its precision and accuracy places it among the leading band saws in its class, with the ability to cut up to 320 mm in width. A key advantage of the machine is the latest generation hydraulic cylinder. The machine features a reinforced vise base and quick-clamping vise.

Machine features

The CORMAK HBS320 metal band saw enables cutting material at any angle within a range from -45° to +60°. The workpiece can be fed manually or using any feeder device. The feed during cutting occurs gravitationally, based on oil flow in the hydraulic cylinder. The operator starts the machine by pressing the start button and sets the cutting speed. Upon cycle completion, the machine automatically stops, and the operator returns the arm to the starting position.

Saw arm is made from a very solid, one-piece gray cast iron casting. Together with a 27 mm wide cutting blade, it reliably handles mass series cutting of structural steel, stainless and tool steels. The vise is mounted on an adjustable bed and equipped with a fast clamping mechanism. Blade guides feature ball bearing systems and carbide inserts, ensuring excellent precision and cut straightness. This dramatically improves blade tracking, blade life, accuracy, and cutting quality. Carbide guides significantly reduce wear of both the machine and the blade.

The base is a rigid welded steel sheet construction. Inside is a separate coolant tank with an electric pump. The upper part of the base forms a tray for draining coolant and collecting metal chips formed during cutting. A work table made of cast iron with a swiveling arm and a control panel is mounted on the base.

Feed rate is controlled from the operator panel. Two cutting blade speeds, 44 and 88 m/min, are selectable. When the arm reaches its lowest position – having completed a cut – the blade drive shuts off automatically. Safety features include blade guards and micro-switches, which stop the motor at the end of the cutting cycle or if any guard is opened. Additional protection involves automatic shut-off in case of blade breakage.

Technical specifications

- Maximum diameter (perpendicular cut): Ø 260 mm

- Maximum height x width (perpendicular cut): 320 x 160 mm

- Power supply: 3-phase 400V

- Total power: 1.5 kW

- Arm descent adjustment: hydraulic cylinder

- Blade dimensions: 2740 x 27 x 0.9 mm

- Blade speed: 44 / 88 m/min

- Vise base height: 920 mm

- Dimensions (L x W x H): 1400 x 880 x 1550 mm

- Weight: 280 kg

Cutting parameters

| Angle | Max Ø | Max height x width | Max square |

|-----|-----|-----|-----|

| 0º | 260 | 320 x 160 | 255 x 255 |

| 45º R | 210 | 210 x 200 | 210 x 210 |

| 60º R | 135 | 135 x 130 | 130 x 130 |

Ljdpfxji D Dgwj Afrjrg

| 45º L | 160 | 220 x 130 | 160 x 160 |

The price shown is NET (excluding VAT). Transport costs are not included.

For further information, please contact us by phone or email. We invite you to view our full offer on our website.

Annonsen ble oversatt automatisk. Oversettelsesfeil kan forekomme.

Machine features

The CORMAK HBS320 metal band saw enables cutting material at any angle within a range from -45° to +60°. The workpiece can be fed manually or using any feeder device. The feed during cutting occurs gravitationally, based on oil flow in the hydraulic cylinder. The operator starts the machine by pressing the start button and sets the cutting speed. Upon cycle completion, the machine automatically stops, and the operator returns the arm to the starting position.

Saw arm is made from a very solid, one-piece gray cast iron casting. Together with a 27 mm wide cutting blade, it reliably handles mass series cutting of structural steel, stainless and tool steels. The vise is mounted on an adjustable bed and equipped with a fast clamping mechanism. Blade guides feature ball bearing systems and carbide inserts, ensuring excellent precision and cut straightness. This dramatically improves blade tracking, blade life, accuracy, and cutting quality. Carbide guides significantly reduce wear of both the machine and the blade.

The base is a rigid welded steel sheet construction. Inside is a separate coolant tank with an electric pump. The upper part of the base forms a tray for draining coolant and collecting metal chips formed during cutting. A work table made of cast iron with a swiveling arm and a control panel is mounted on the base.

Feed rate is controlled from the operator panel. Two cutting blade speeds, 44 and 88 m/min, are selectable. When the arm reaches its lowest position – having completed a cut – the blade drive shuts off automatically. Safety features include blade guards and micro-switches, which stop the motor at the end of the cutting cycle or if any guard is opened. Additional protection involves automatic shut-off in case of blade breakage.

Technical specifications

- Maximum diameter (perpendicular cut): Ø 260 mm

- Maximum height x width (perpendicular cut): 320 x 160 mm

- Power supply: 3-phase 400V

- Total power: 1.5 kW

- Arm descent adjustment: hydraulic cylinder

- Blade dimensions: 2740 x 27 x 0.9 mm

- Blade speed: 44 / 88 m/min

- Vise base height: 920 mm

- Dimensions (L x W x H): 1400 x 880 x 1550 mm

- Weight: 280 kg

Cutting parameters

| Angle | Max Ø | Max height x width | Max square |

|-----|-----|-----|-----|

| 0º | 260 | 320 x 160 | 255 x 255 |

| 45º R | 210 | 210 x 200 | 210 x 210 |

| 60º R | 135 | 135 x 130 | 130 x 130 |

Ljdpfxji D Dgwj Afrjrg

| 45º L | 160 | 220 x 130 | 160 x 160 |

The price shown is NET (excluding VAT). Transport costs are not included.

For further information, please contact us by phone or email. We invite you to view our full offer on our website.

Annonsen ble oversatt automatisk. Oversettelsesfeil kan forekomme.

Tilbyder

Merk: Registrer deg gratis eller logg inn, for å få tilgang til all informasjon.

Send forespørsel

Telefon & Faks

+48 25 63... annonser

Disse annonsene kan også være av interesse for deg.

Annonse

Shildon

Shildon

887 km

Senter dreiebenk

ColchesterMastiff 1400

ColchesterMastiff 1400

Annonse

Hessisch Lichtenau

Hessisch Lichtenau

1 035 km

Sirkulær gjennom vibrerende etterbehandlingsmaskin

WALTHER TROWALCLS-230

WALTHER TROWALCLS-230

Annonse

Siedlce

Siedlce

1 255 km

Båndsag

CORMAKBS-128HDRC 400V

CORMAKBS-128HDRC 400V

Annonse

Wasbek

Wasbek

718 km

Konvensjonell dreiebenk - Sinus 400/1500 D

KnuthSinus 400/1500 D

KnuthSinus 400/1500 D

Annonse

Wesel

Wesel

991 km

Vibrerende etterbehandlingssystem

ERBAEVP-RA 350 Rundvibrator mit Separierung

ERBAEVP-RA 350 Rundvibrator mit Separierung

Annonse

Enschede

Enschede

923 km

Perle- og flensmaskin

OstasKMRH 4,0

OstasKMRH 4,0

Annonse

Hessisch Lichtenau

Hessisch Lichtenau

1 035 km

Hydr. Verkstedpresse, Broachingpresse, Groove broaching presse, For broaching kilespor i passasje

Eigenbau MaVo5t-20

Eigenbau MaVo5t-20

Annonse

Lemmer

Lemmer

865 km

Båndsag

MepShark 330HH

MepShark 330HH

Annonse

Nauen

Nauen

923 km

Kontroller for lagerheiser

fse-Lifte Alle Typen

fse-Lifte Alle Typen

Annonse

Mindelheim

Mindelheim

1 390 km

Dobbel gjæringsbåndsag

MIOTALS 255 DG

MIOTALS 255 DG

Annonsen din har blitt slettet

Det har oppstått en feil